The downhill ski is an interesting flight vehicle. Like a soap box derby racer a ski has no propulsion and relies on the force of gravity to propel the skier down the slope. For both soap box derby racing and downhill racing -but not recreational skiing - the objective is to maximize average speed to get to the bottom of the hill in record time. Therefore a winning design needs to have minimum drag. A soap box derby run is usually straight with drag coming from the wheel bearings and aerodynamic drag. However downhill ski courses have many turns. Therefore a winning downhill ski needs to be able to turn the direction of the skier's motion with minimum added drag caused by turning.

Downhill skis achieve turning with minimum added drag by carving the ski much like a train going around a curve. As a train goes around a curve each car is going in a different direction with the force on the wheels of each car normal to the arc of the curve acting to turn the direction of motion of the car with very little drag. Similarly in a perfectly carved turn, the ski follows a path like a train track with no side slipping and very little loss in speed through the turn. However if skiers want to loose speed, they can skid the ski though the turn to create additional drag.

The elegance of low drag pure carve control ski maneuverability and speed control comes at the price of a high level of balance, coordination, physical strength and ski skill training needed to optimally execute carve control skiing maneuvers especially on steeper terrain. Failure to execute these maneuvers correctly can lead to falls and injury.

Ski Control System design objectives

The design objective of the Ski Control System is to add control surfaces to recreational skis that will work with the carve of the ski to provide enhanced control of both maneuverability and speed much like the control surfaces on aircraft. The SCS commercial objective is to make skiing easier to learn and both safer and more fun to enjoy. Inevitably the SCS control surfaces will add drag, but the objective of recreational skiing is not to go as fast as possible but to go as fast as the skier wants.

Summary Design Description

The left figure below shows REV 19 SCS units mounted on skis with the special Look bindings used by Heavenly for their rental skis/boots and therefore also used for the four seasons (1993-1996) of SCS beginning lessons given by the Heavenly ski school.

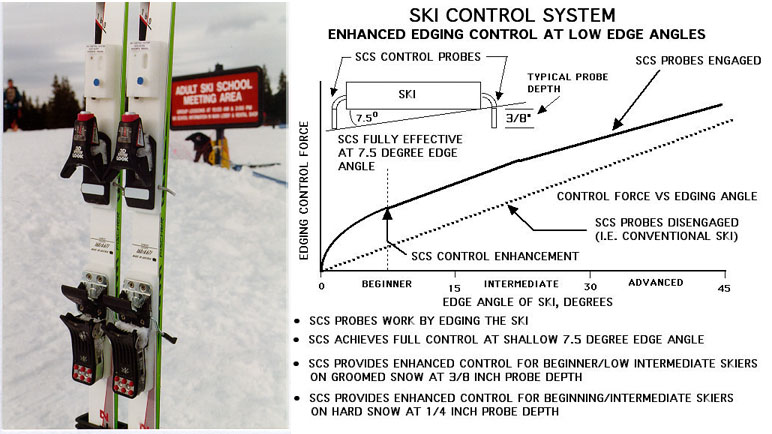

The SCS features spring loaded control probes (similar in operation to loose ski brakes) mounted on each side of the ski near the center of pressure. The probes are airfoil shaped and only penetrate the snow about 3/8 inch with a preload of about 1.5 pounds per pair. Therefore when flat skiing the four probes on both skis create a total of about 3 pounds of drag which help keep beginning skiers forward and over their skis with their center for gravity at or ahead of the center of pressure of the skis (i.e. stable). The additional 3 pounds of drag only requires about an additional 1 degree of ski slope (i.e. skiers weight times the sine of the slope) which only significantly slows beginners down (which they appreciate) on the most gentle beginner slopes. On truly flat terrain the skier can use their ski pole to push the blue button which retracts the probes. Using the ski poles to push in the slots reengages the probes.

Enhanced SCS Edging Control for turning:

The SCS control probes enable a skier to achieve significant turning with only gentle edging of the skis. As shown in the right figure edging the skis only a few degrees (which is all that many beginning skiers feel comfortable with) extracts the probes on the outside edges and reduces the drag forces on those outside probes so the greater drag on the inside probes turns the skis in the direction the skier is edging. With edging of only a few degrees the turning effect of edging the ski is minimal, but the unbalanced drag of the probes enables the skier to turn the skis. At an edging angle of only about 7.5 degrees the probes are fully effective in creating turning torque and they along with the still small edging effect of the skis provide quite effective turning. As skiers progress in their ability to edge the ski through beginner and into intermediate skill levels, the SCS probes continue to provide a noticeable additional turning torque that makes the skis turn faster than they would with ski edging torque alone.

The enhanced flat ski edging control achieved with the SCS probes is very helpful under hard snow conditions. Depending on the terrain, the SCS probes enable beginning and low to middle intermediate skiers to flatter ski on hard snow (to avoid catching an edge) and still retain good turning ability.

The differential torque of the SCS probes turns the skis, but not the direction of the skiers motion. The result is a skidded turn where the edges of the ski and also the probes provide lift (force perpendicular to the direction of motion) that turn the direction of travel in the turned direction the skis are now pointing.

Enhanced SCS Speed Control:

Even gently skidding the airfoil SCS probes creates both lift (as mentioned above) and also additional drag that supplements the drag of the skidding skis to control speed. The airfoils of the probes are actually outwardly canted at 15 degrees which does not significantly increase straight ski drag, but rapidly increases probe drag as the skis are skidded in a turn. I can conservatively ski down a low intermediate slope doing gentle "S" turns with moderate skidding allowing the SCS probes to act as speed brakes on an airplane to keep my speed under control.

SCS Equipment configurations

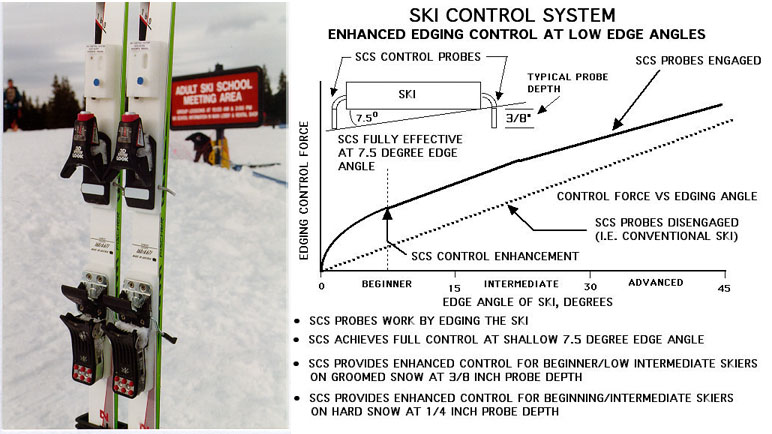

As shown below over the years I demonstrated the compatibility of the SCS with many different skis and bindings in an effort to encourage ski equipment manufacturers to include the SCS in their product line.

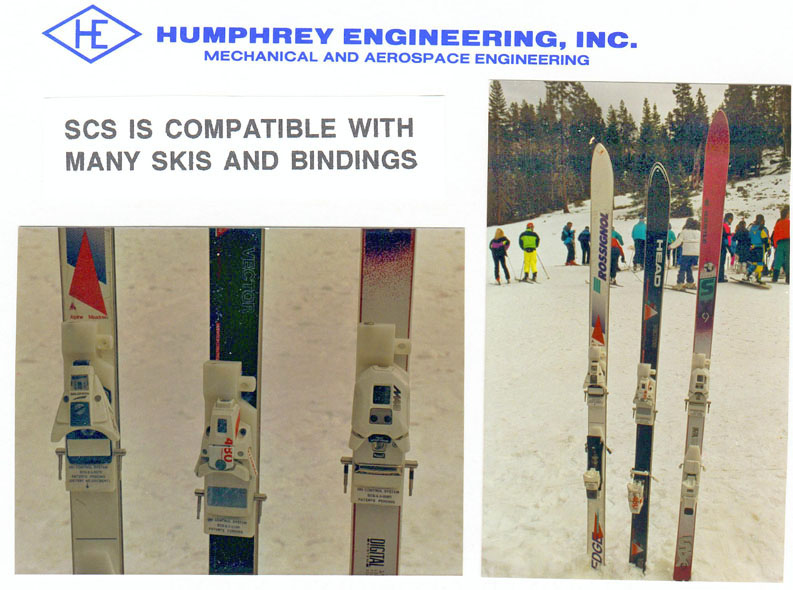

Since the SCS is a mechanical device (functionally similar to a loose ski brake), the ski binding is the logical component to incorporate the SCS probes and control mechanism. However there are significant advantages of providing a feedback between the carve of the ski and the preload on the SCS control probes. This would enable intermediate skiers to achieve very low flat ski drag and yet have even stronger supplemental SCS control when they put their skis on edge. This Carve Control Amplification (which was the subject of our 4th US patent) led me to build an integral ski prototype which demonstrated the ability to house the entire SCS mechanism and control probes in the body of the ski (but did not demonstrate the CCA interaction). In May 1992 I was invited to attend the Professional Ski Instructors of America western convention at Mammoth to present and demo the SCS and as shown below I took this integral ski prototype along as part of that presentation.

The REV 19 Ski Control System used for all four seasons of SCS beginning ski lessons at Heavenly and the two seasons at Diamond Peak was for a prototype an easily producible machine part. Through my company I developed and provided production drawings and then contracted the detailed machining of both the stainless steel and plastic parts to a top notch local machine shop.

Through my company I then performed final assembly and ski mounting to complete the SCS production process. The picture below shows me after completing the 100th Rev 19 SCS unit on February 10, 1996.

Preparation for the planned 1996/1997 ski season

Over the summer of 1996 I prepared for what I understood would be a continuation of the SCS program at Heavenly and Diamond Peak for the 1996/1997 ski season with the SCS skis now being rented to SCS beginning skiers through the rental shops, then used in SCS beginning lessons as in previous years and then used by the beginning skiers for the rest of the day after their lessons. I refurbished the SCS skis from the 1996 ski lessons (cleaned and lubricated the parts and replaced any worn actuator cables) and added new equipment for the 1997 season.

The picture below shows the 22 pairs of SCS equipped skis (21 rental pairs and one for instructor evaluation) that were provided to Heavenly Ski Resort on November 21, 1996 for beginning SCS student lessons and follow on student rental for the 1997 ski season.

This picture shows the 20 pairs of SCS equipped skis featuring the new ELAN "SCX" parabolic ski (which we understood the Diamond Peak ski school requested) delivered to Diamond Peak (in two batches of 10 on November 20, 1996 and on December 17, 1996) for beginning SCS student lessons and follow on student rental for the 1997 ski season. We also included a single ski demo unit with a plaque presenting some of the very supportive comments from beginning students who took SCS lessons at Diamond Peak in the previous two seasons.

Somehow what I understood to be the planned 1997 ski season SCS lesson and ski rental program apparently did not take place at either Heavenly or Diamond Peak. The SCS equipped skis were returned and have been sitting at my home now for 16 years.

Design Summary:

Although the planned 1997 lesson and rental program (using the same REV 19 SCS units successfully used for the four previous seasons (see student lesson comments) apparently did not take place, the over 40 units produced and delivered I believe demonstrated that SCS units could be produced in quantity. I have believed since the late 1980s that the best approach to broad public access to I believe the enhanced control and safety benefits of SCS technology is to encourage a ski equipment manufacturer to create an SCS production design and then mass produce ski equipment (either bindings, skis or a combination) that incorporates SCS control probes. The prototype design and student lesson program my company funded from the late 1980s to 1997, I believe provided a solid foundation for such a commercial production program

Thank you for reviewing this SCS pictorial design description.

Return to the SCS home page summary discussion where you left off.